Commissioning an inversor goes beyond just turning it on. In today’s solar and energy-storage setups, it signals the shift from putting things together to actual use. For folks building projects, running facilities, or homeowners going green, knowing this step cuts down on holdups. It also drops ongoing dangers and backs steady work from the system.

This piece explains what starting up an inverter truly covers. It looks at what goes on at the site. And it shares what people might see in the early hours and days of running.

What Does “Commissioning an Inverter” Really Mean?

Commissioning means the organized way of checking, proving, and kicking off an inverter after setup. The aim is to make sure every part—from wires to link setups—runs as planned. And it hits safety and work levels.

Unlike regular upkeep, this happens just once per new setup. It lays the base for solid running through the whole life of the 太阳的 or energy-storage job.

Why Commissioning Matters More Than Most People Think

An inverter acts as the main control for any solar or storage setup. A tiny setting slip or link problem can hurt energy output, life span, and even rule following. Solid commissioning lowers these threats by spotting issues before the system starts for real.

Here is how commissioning helps with safer and easier running:

Key Benefits

- Right system work from the start A proper solar inverter startup process makes sure voltage, current, and power match the real spot conditions.

- Better lasting dependability Setups with noted commissioning often face fewer stops. And they show steadier output lines.

- Improved grid link Right checks stop problems like backward power move, light flickers, or power level shifts.

What Happens During Inverter Commissioning?

Before getting into parts, picture a true spot scene. Workers finish cables. Techs sign into the inverter screen. And they follow a list one by one. This forms the heart of any inverter commissioning checklist, no matter the setup size.

1. Pre-Power Checks

Workers look over real setup items before turning on power.

Usual steps cover:

- Checking AC and DC wires

- Looking at twist levels on ends

- Viewing ground spots

- Making sure DC lines have right sides

A basic table can show this part:

| Inspection Item | What Technicians Look For | Por qué importa |

|---|---|---|

| DC Connections | Sides, cover, tags | Stops start errors and line mix-ups |

| AC Cabling | Order of phases, switch levels | Makes sure smooth grid tie |

| Communication Lines | Strong ties, right spots | Lets watching and far control |

2. Parameter Configuration

Once wires pass the look-over, techs set software options. Many folks skip this part. Yet it greatly shapes how well things run.

Common setup items:

- Grid outline settings

- MPPT start voltage

- Reactive power options

- Guard limits

- Link ways (Modbus, RS485, TCP/IP)

In bigger jobs, techs often do a setting check test. This confirms options match the plan paper.

3. System Startup

After setup, the inverter gets power for the first time.

During start, workers usually watch:

- Slow rise action

- MPPT follow reply

- Live voltage and beat

- Heat spread and fan moves

A quick test time—often 15 to 30 minutes—shows if the inverter acts normal under sun or weight.

4. Performance Verification

This part checks if real work lines up with job hopes.

Usual moves:

- Noting running info

- Matching output to guessed lines

- Trying grid help roles

- Proving link with the watch system

Any shifts get fixed before hand-off.

What Users Can Expect After Commissioning

From setup to last pass-off, hopes often split into three groups. These tips come from true job scenes seen in business, factory, and home setups.

A. First-Day Output Fluctuation

It’s common for the inverter to tweak its MPPT moves in the early hours. Power out might seem a bit uneven. But it settles fast.

B. Initial Monitoring Data Review

In the first day, setup owners often get their first full report. Techs look for odd drops, link losses, or shade hits.

C. A Short Learning Period

Over the first week, the setup keeps fitting to local light and weight ways. This happens often. And it’s part of the usual settle process.

Common Issues Found During Commissioning

To aid readers in judging their setups with more ease, here are usual problems found during inverter commissioning:

- Loose ends that lead to off-and-on stops

- Wrong grid rule pick

- Software version mix-ups between inverter and watch system

These troubles are mostly simple to fix when caught soon. This shows why a planned way matters in commissioning.

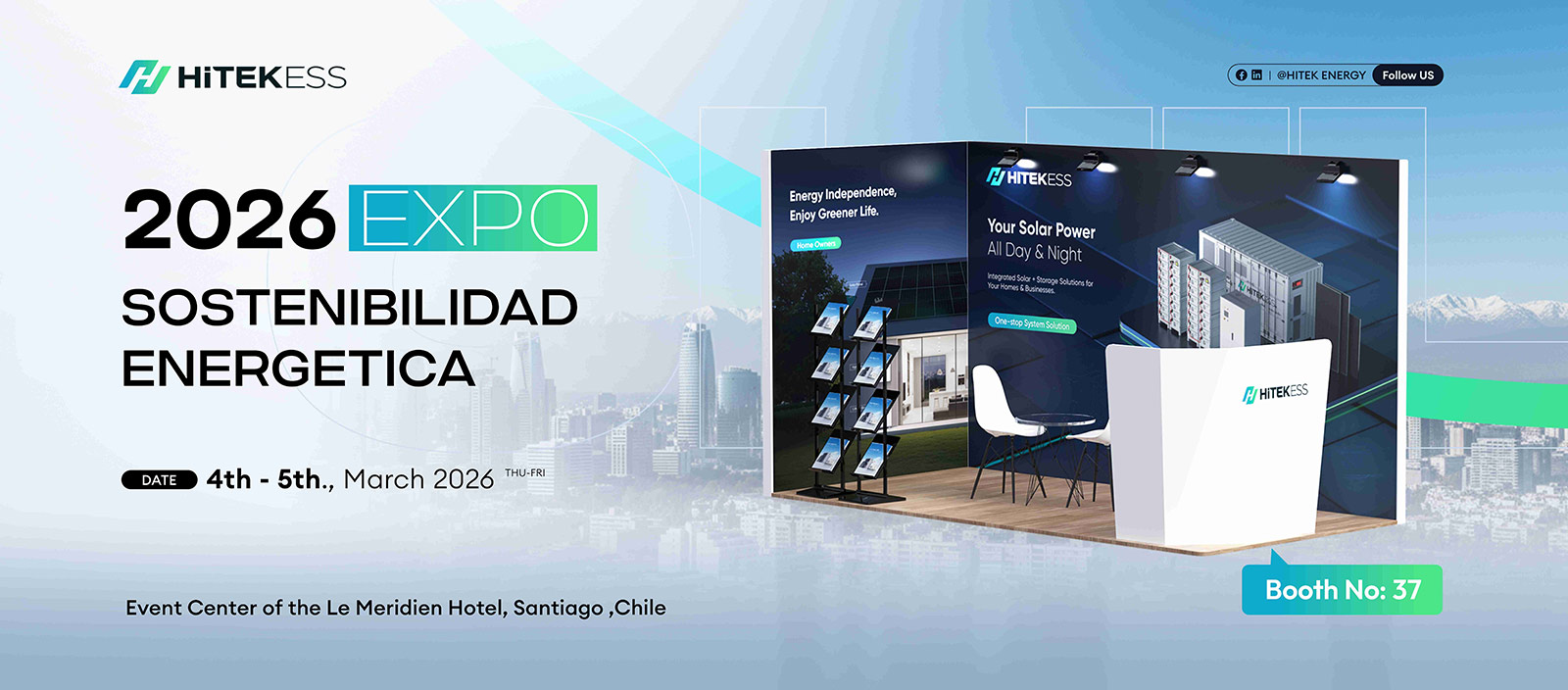

Introducing HITEK ENERGY CO., LTD

HITEK ENERGY CO., LTD. (en inglés) is a global provider of solar-energy and energy-storage solutions. HITEKESS designs and manufactures advanced inverter and ESS technologies aimed at industrial, commercial, and residential markets.

With a focus on high-quality engineering, long-term reliability, and service support, HITEK ENERGY has built a strong presence in international clean-energy projects. Its solutions integrate efficient power electronics, modular design, and smart monitoring, helping customers achieve stable and scalable renewable-energy systems.

This background is important because proper commissioning paired with high-quality equipment significantly elevates project performance and brand trust for both installers and end-users.

Conclusión

Commissioning an inverter is an organized, very key stage. It sets the base for lasting system work. When handled right, it backs safer running, stronger energy out, and better grid ties. If the setup is on a roof solar group, a mixed ESS job, or a business energy shift, treating commissioning with care brings clear gains over the setup’s life.

FAQs About Commissioning an Inverter

What is the main purpose of commissioning an inverter?

The purpose is to verify wiring, configure parameters, and confirm that the system performs safely before long-term operation. A complete solar inverter startup process minimizes the chance of early-stage faults.

How long does inverter commissioning usually take?

Most small to mid-scale systems require 2–4 hours, including physical checks and parameter setup. Larger commercial projects may need a full day to complete the inverter commissioning checklist.

Can an inverter run without commissioning?

It can power on, but operation may be unsafe or inefficient. Incorrect grid settings or wiring mistakes can lead to shutdowns, unstable output, or reduced energy yield.

What problems are most commonly found during commissioning?

Typical issues include loose terminals, incompatible settings, or sensor misreads. These are easily fixed when detected early, which is why many installers follow a structured inverter installation best practices workflow.

Do users need to be on-site during commissioning?

Not necessarily. Many systems allow remote verification through monitoring platforms, though some companies prefer clients to be present for the final handover.

HITEK ENERGY’S BEST-SELLING SOLAR INVERTERS

- Deye Single Phase 220V 230V 5kw 6kw 8kw Solar Hybrid Power Inverter for Home Use Ready for DeliveryModel: SUN-6K-SG03LP1-EU

- Deye 5kw 8kw 10kw 12kw 16kw 20kw Hybrid Energy Storage LV Battery Voltage 48V Range Hybrid Inverter EU/UsModel: DEYE-SUN-10K-SG02LP1-EU-AM3

- EU Deye Sun-3.6/5/6/7.6/8K-Sg05lp1-EU Hybrid Solar Inverter 5kw 6kw 8kw Single Phase WiFi 48V IP65 Solar Hyhbrid InverterModel: SUN-6K-SG03LP1-EU

- Hitek 120/240V Split Phase Us Voltage Home Storage Hybrid Solar Inverter 10kw 15kw 20kw Hitek Energy off Grid InverterModel: HT-IN10KW-US

- Deye 380VAC 10000W 3phase Hybrid Power Solar Inverter AC/DC Inverters 380V/400V 8kw 10kw 12kw on off Grid Inverters Hybrid Solar InverterModel: SUN-10K-SG04LP3-EU