Paneles solares power homes and cut bills, but what happens when they wear out? After 25-30 years, those shiny cells inside start to fade. You might worry about the waste piling up or the hit to your green cred. Fair enough. End-of-life panels add up fast—millions of tons by 2030. Yet recycling flips that script. It pulls out silver, silicon, glass, and more, turning scrap into fresh starts. This guide digs in. We’ll cover why it matters, smart ways to do it, and the real wins. If you’re a homeowner eyeing upgrades or a business chasing net-zero, here’s your roadmap to smarter solar cycles.

Understanding Solar Cells and the Need for Recycling

Solar cells capture sunlight and turn it into electricity. Crystalline silicon types dominate—thin wafers sandwiched between glass and metal frames. They hum along for decades, but heat, weather, and time take a toll. Efficiency drops below 80%, and that’s your cue to swap.

The Growing Pile of End-of-Life Panels

Global installs hit 1 terawatt last year. That means waves of old panels hitting landfills soon. Without action, toxic bits like lead or cadmium leach out. Rain pulls them into soil and water. Bad news for rivers, fish, folks downstream. But hold on—90% of a panel is reusable stuff. Glass alone makes up 70%. Skip the dump, and you dodge fines too. EU rules mandate collection by 2030. Stateside, California’s ahead with deposit fees.

Why Reuse Beats Starting Over

Fresh mining guzzles energy—twice what recycling saves. Pull silicon from old cells, and you cut CO2 by 90%. It’s not just earth-friendly. It keeps costs down for new builds. Think loops: old panel to new one in months, not years.

Key Methods for Solar Cell Recycling

No one-size-fits-all here. Plants mix heat, crush, and chemicals to tease parts apart. Each pulls different yields, fits budgets.

Physical Separation: Simple and Low-Impact

Start mechanical. Trucks haul panels to yards. Hammers or rollers smash frames. Screens sift glass from metal. Magnets snag steel, eddy currents grab aluminum. It’s dry work—no solvents. Yields 95% glass, 80% metals. Quick turnaround, low cost. But silicon stays glued in shards. Good for bulk waste, not pure pulls.

Thermal Processes: Heat to Break Bonds

Ramp up the temp. Pyrolysis bakes paneles at 500°C. Polymers vaporize, leaving clean layers. Then plasma torches melt metals at 1,500°C. Silver drips out pure. A France’s company runs this—recovers 95% materials. Heat eats power, though. And fumes need scrubbers. Still, it’s cleaner than landfilling.

Chemical Breakdown: Precision for Valuables

Soak in acids. Hydrochloric strips encapsulants, nitric grabs silver. Rinse, dry, reuse. Labs hit 99% silicon recovery this way. China’s pushing it big—plants process 100,000 tons yearly. Drawback: waste acids need neutralizers. Go green with bio-leaches—bacteria eat glue without harsh chems.

Check this table for a quick side-by-side. It shows yields and fits.

| Method | Key Steps | Material Recovery Rate | Energy Use | Best For |

|---|---|---|---|---|

| Physical | Crush, sort, magnet | 80-95% (glass/metals) | Bajo | Large volumes |

| Thermal | Bake, melt, separate | 90-95% overall | Alto | Metals like silver |

| Chemical | Acid soak, rinse | 95-99% (silicon) | Medium | High-purity reuse |

Physical wins on ease. Chemical shines for value grabs.

Environmentally Friendly Treatment Paths Forward

Green recycling isn’t pie-in-sky. It’s here, scaling up. Focus on low-waste loops that fit solar’s clean vibe.

- Closed-Loop Systems: Shred panels, feed bits back to makers. No off-site hauls. A company in Belgium does this—handles 10,000 tons in 2025, zero landfill. Cuts truck miles, emissions drop 50%.

- Bio-Based Cleaners: Swap acids for enzymes or fungi. They nibble polymers gentle. Early trials recover 85% without toxics. Scalable soon, per labs.

- Modular Plants: Small setups near farms or installs. Mobile crushers process on-site. France tests these—saves 30% transport fuel.

- Policy Nudges: Deposits fund hauls. EU’s WEEE directive recycles 80% by weight. Copy that, and jobs bloom—10,000 new ones by 2030.

These paths dodge old pitfalls. No more buried hazards. Just steady streams of clean pulls.

Tapping the Potential Value in Reuse

Recycling isn’t charity—it’s bankable. Old cells hold gold, literally. Silver alone: 20 grams per panel, worth $15. Times millions? Big bucks.

Material Riches Pulled Back

One ton yields 300 kg glass, 150 kg aluminum, 4 kg silicon, 0.3 kg silver. At market, that’s $500-1,000 per ton. Scale to U.S. waste: $60 million industry by 2030, $2 billion by 2050. Reuse silicon wafers directly—saves 95% energy over mining. Glass grinds into road fill or new frames. Metals melt for wires.

Job Sparks and Green Growth

Plants need sorters, techs, haulers. PV recycling could add 100,000 jobs EU-wide by mid-century. U.S. follows suit. Training programs pop up—welders to chemists. Local hires cut commutes, boost towns.

Economic Loops for Installers

Homeowners: Trade old panels, get credits on new. Businesses: Tax breaks for certified recycles. IRENA says it pays back in three years. Plus, brands shine—eco-labels draw buyers. Your solar setup? It funds the next.

Deep cut: Circular models extend life. Refurbish 80% efficient cells for off-grid spots. Value doubles—saves $11 billion UK by 2050.

Hurdles in Solar Cell Recycling and How to Clear Them

It’s not all smooth. Costs bite, tech lags in spots. But fixes roll out.

Upfront Costs and Scale Snags

New plants run $10-20 million. Small volumes hike per-ton fees. Solution: Grants seed funds. U.S. DOE pumps $20 million yearly. Cluster ops—shared shredders drop costs 40%.

Tech Gaps for Thin-Film Types

Silicon’s easy; cadmium telluride? Trickier, toxics hide. Advances: Selective dissolves pull 95% without spills. Pilots in Arizona test it.

- Collection Woes: Panels scatter post-install. Apps track them, like PV Cycle’s network—covers 90% Europe.

- Standards Drift: Rules vary. Global certs, like ISO 14001, align them.

- Market Flux: Silver prices swing. Lock contracts early.

Push past these, and recycling hits 95% by 2040. It’s doable.

Challenges of Mixed Waste Streams

Not all panels play nice. Some mix silicon with organics. Pyrolysis handles it, but watch emissions. Filters catch 99%. And logistics: Rural farms mean long hauls. Drones scout sites now—cuts guesswork.

Steps to Get Started with Recycling

Ready to act? Audit your setup. Check warranties—many cover take-backs. Partner with certified haulers. Track via apps. Small step: Label panels with IDs for easy trace.

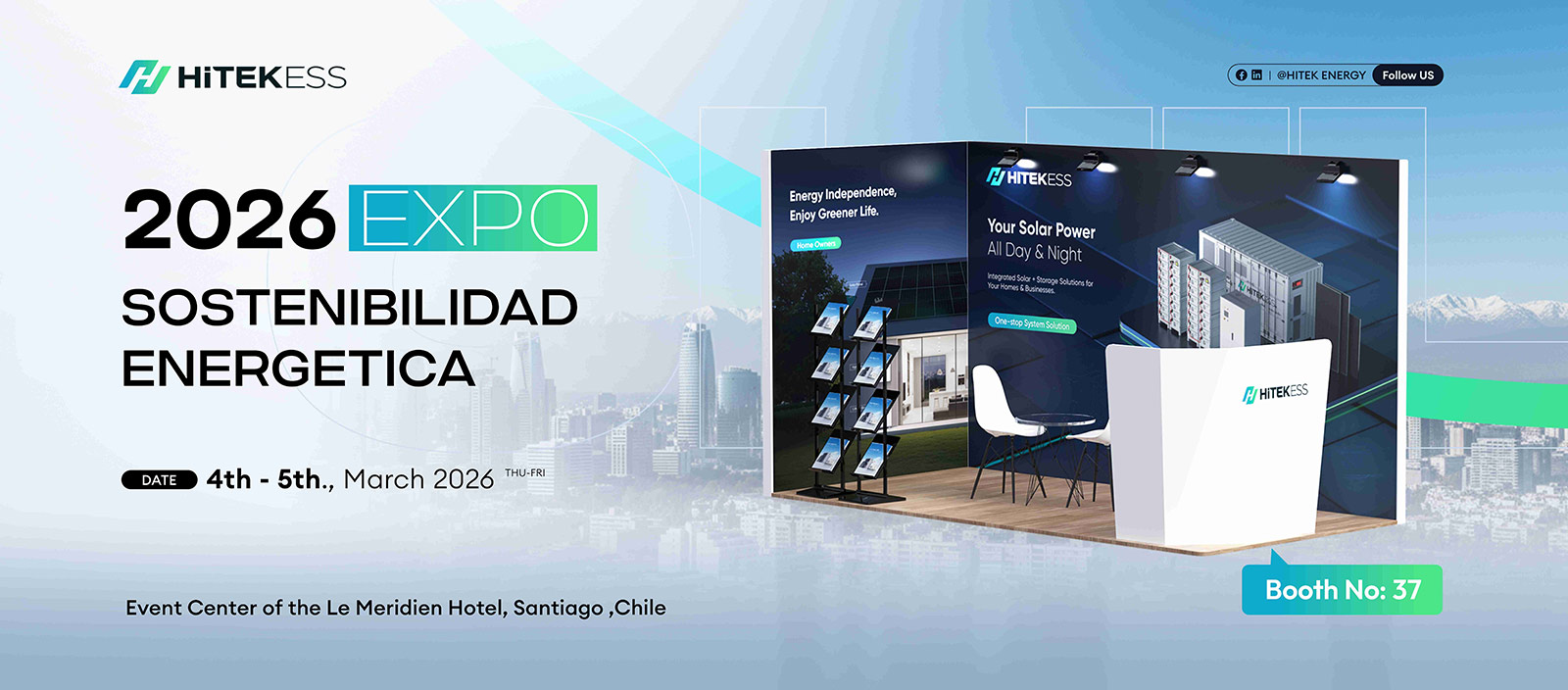

Introducing HITEK ENERGY CO., LTD

Before conclusion, a nod to a key player in energy storage. HITEK ENERGY CO.,LTD crafts lithium battery products with a green bent. Out of China, they build prismatic LiFePO4 packs for solar tie-ins—safe, long-haul units that store what panels catch. ISO 14001 certified, they chase resource loops and low-carbon builds. It’s the backbone for setups that last, recycle-ready.

Putting It All Together

Solar cell recycling closes the loop on clean power. We’ve unpacked methods from crush to chem, green tweaks that slash waste, and values from jobs to silver hauls. It’s more than duty—it’s smart play. Hurdles exist, but tools sharpen daily. Your next panel? Let it feed the chain, not the ground. That way, solar stays true green, powering tomorrow without the footprint.

Frequently Asked Questions on Solar Cell Recycling and Reuse

Q: What’s the first step in solar cell recycling and reuse for my old panels?

A: Call a certified collector. They’ll haul and sort—physical methods pull glass fast. Keeps it simple, earth-kind.

Q: How do environmentally friendly methods boost solar cell recycling and reuse?

A: Bio-cleansers skip acids, closed loops cut hauls. Yields hit 95%, no toxics left behind.

Q: Can solar cell recycling and reuse really create jobs?

A: Yes—plants need hands for sorting, melting. Expect 10,000 new spots by 2030, steady pay in green work.

Q: What’s the potential value in solar cell recycling and reuse materials?

A: Silver and silicon alone top $1,000 per ton. Scale up, and it’s billions—funds new tech easy.

Q: Are there hurdles in solar cell recycling and reuse for thin-film types?

A: Toxics complicate it. But selective chems recover 95% safe. Pilots prove it works now.

HITEKESS FAVORITE SOLAR BATTERIES

- Hitek Energy Ess 5kwh 10kwh 15.36kwh 15kwh Vertical Solar Power Panel Hybrid Inverter Home LiFePO4 Rechargeable Energy Battery 48V 51.2VModel: HT-15KWH

- Hitek 30kwh 25kwh 20kwh 15kwh High Voltage LiFePO4 Stackable Lithium Solar Panel Battery House System Storage Stacked Battery 51.2V 48VModel: HT-20HS

- Commercial 50kVA 100kVA Solar Battery Energy Storage System 50kw 100kw Hybrid All in One Solar Power System 100kwh 200kwh 229kwh 241kwh Lithium Battery BackupModel: HTAC-50/100-OD

- Hitek 5kwh 10kwh 15kwh Residential 5kVA 10kVA 51.2V 100ah 200ah 280ah Lithium Battery Energy Storage Solar SystemModel: HT-15KWH

- Hitek Power 51.2V 280ah 300ah 15kwh LiFePO4 Solar Energy System Solar Battery EV 280K 6000 Cycles 51.2VModel: HT-15KWH